To Shim Or Not To Shim, Is That Really The Question?

A customary practice in the installation of commercial doors whether wood or steel is shimming of the door hinges. This is so common the industry actually has a term for it, i.e., throwing the hinges.

What is behind this practice? It is the field-fix for a door that will not close properly into the frame. Or, in another instance, it is used to improve the reveal, i.e., the gap between the door and the frame, when the door is closed and latched.

What is the root cause of the need to throw hinges? Simple, the frame is not plumb and square. It is not the door or the hinges. Doors are square and commercial hinges are robust products. The misalignment comes from the frame.

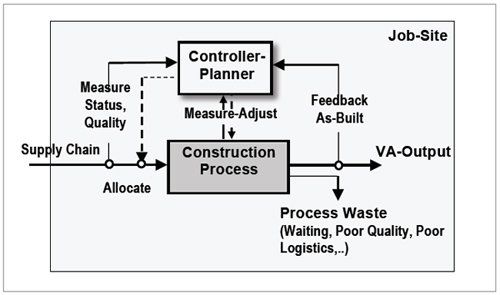

Why are the hollow metal frames not plumb and square? The frames, regardless of manufacturer, i.e., Steelcraft, CECO, Curries, Mesker, Premier, MPI, Dumbarton, and Timely, were installed in a plumb and square condition. Unfortunately, during the construction process, the frames can get bumped and easily thrown out of alignment. In another case, workers have been known to wedge an object (such as a broom handle) between the door and frame to hold the door open. This wedge puts a concentrated load on the frame leading to frame distortion (and the need to compensate the frame damage) by throwing hinges.

Types of Shims

1. Whatever you can find – Exactly what it sounds like. At times this turns out to be cardboard because there is always cardboard dunnage somewhere on the job site. And unbelievably, this is acceptable, as long as the door is not in an area with high moisture, or a fire rated opening.

2. Plastic shims - Plastic shims are not affected by moisture and won’t compress over time like a cardboard shim could do. Plastic shims, like cardboard shims, should not be used on fire rated openings.

3. Wood shims – Wood shims are a common solution in residential buildings but are not recommended for commercial buildings and doors. Wood shims can be difficult to cut to size (the shims should not be visible by the customer), they can tend to breakdown with moisture, and they are not acceptable for fire rated openings.

4. Steel shims – Steel shims are the best choice when throwing a commercial door hinge. Steel shims should be made from galvanized or galvannealed steel, so they do not rust with time. A rusting shim could compromise the relative position between the door and the frame. Shims made from steel are the only shims allowed on a fire rated opening.