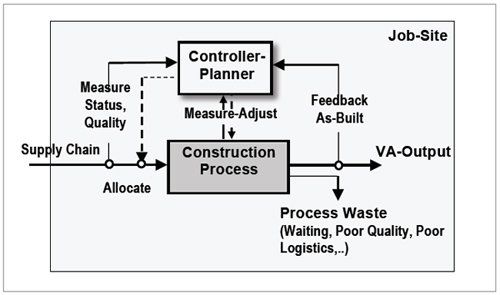

Here are some excerpts from their research:

“Construction is a massive and fast-paced operation. Understandably, it must be realized that minor trade damage is part of construction and needs to be accounted for on every project. The framing subcontractor should include an allowance in their bid for repairing the inevitable cases of minor trade damage. An allowance in the form of a specific number of worker hours and the cost of materials should be established by the general contractor.”

“The framing subcontractors can then compute the appropriate value of the allowance to include in their bids. For best cost control the framing subcontractor’s bid should stipulate the number of hours allocated for the repair work, not a fixed dollar value. It should be recognized that subcontractors tend to use different labor rates when bidding a project than they do when submitting change order requests.”

“Additionally, by including the labor and material value of this allowance in the framing subcontractors’ base bid, the subcontractor will already have the taxes, insurance, overhead, profit, and other markups on this work included in the bottom line of their base bid estimate. Therefore, the time and material charged to this allowance will be done so without any additional markups. Though repairing trade damage is an indirect cost of a project it is still an actual and necessary cost on a project and as such should be viewed as a standard base bid responsibility just as with the direct work.”

“Dents and dings to installed doors and frames are inevitable on a project. A plan should be in place for protecting doors and frames, as well as for making minor repairs. It is preferred that the protection be installed by the door subcontractor, with the maintenance and removal of the protection performed by the general contractor. Since the door subcontractor will not have a presence on the project after completing the door installation, it is not considered appropriate to hold them responsible for maintaining the protection or for damage caused by others.”

“Though this example is specific to the door trade, similar concerns exist with other installed items that might be damaged by different trades. If subcontractors are asked to protect their own work, it is important to also address the, often costly, maintenance and removal of this protection. Be sure to also address the inevitable minor repairs necessary due to trade damage throughout the trades, particularly the trades providing the building finishes.”

The authors suggest trade damage is inevitable and unavoidable. There was a time, in another industry, i.e., automotive, that oil leaking from the engine was accepted an inevitable result of the materials and assembly methods that went into producing internal combustion engines. Thank goodness the industry was unwilling to accept that paradigm!

The construction industry, like the automotive industry, also does not have to accept “inevitable” paradigms. Trade damage does not have to be accepted and a combination of materials/design, methods, and manpower can all contribute to reducing and eliminating trade damage.

If eliminating trade damage around doors and frames is your area of interest, make sure to review the benefits of the Qwikinstall Two-piece Interlocking Welded Hollow Metal frame. It is designed to be installed after most trades have left the construction site so, by design and method, trade damage is greatly reduced or avoided.